How to setup your vacuum table

06 nov.

Bien que cela puisse varier en fonction de votre installation, ces instructions peuvent constituer un guide approximatif pour vous permettre d'être opérationnel en un rien de temps. en un rien de temps.

Si vous avez une question spécifique à laquelle vous n'avez pas trouvé de réponse ici, contactez-nous ou parlez-nous sur le chat en direct.

La série R

- Fixez la table d'aspiration à votre rainure en T ou à votre plaque d'adaptation à l'aide de pinces à fixer sur le rebord de la table.

- Ajoutez et connectez le tuyau fourni de la table à votre aspirateur.

- Retirez les vis sans tête de la surface de la table.

- Placez le cordon en caoutchouc qui ira autour de votre pièce à travailler pour former un bon joint.

- En option, utilisez le tapis en PVC, en cas de fraisage de rupture, qui servira à protéger la surface de la table.

- Posez votre pièce sur la table et mettez votre aspirateur en marche.

La série RAL

- Fixez la table à vide à votre rainure en T à l'aide de pinces sur votre machine hôte et attachez-la à la lèvre autour de la table.

- Ajoutez la connexion du tuyau de la table à vide au collecteur.

- A l'aide du tuyau fourni, connectez le collecteur au Venturi.

- Connectez ensuite le Venturi à votre compresseur.

- Retirez une ou plusieurs (en fonction de la taille de votre pièce) des vis sans tête de la surface de la table.

- Utilisez le cordon en caoutchouc pour créer un joint autour de votre pièce.

- Placez votre pièce sur le dessus.

- Mettez votre compresseur en marche et ouvrez le collecteur et les valves Venturi.

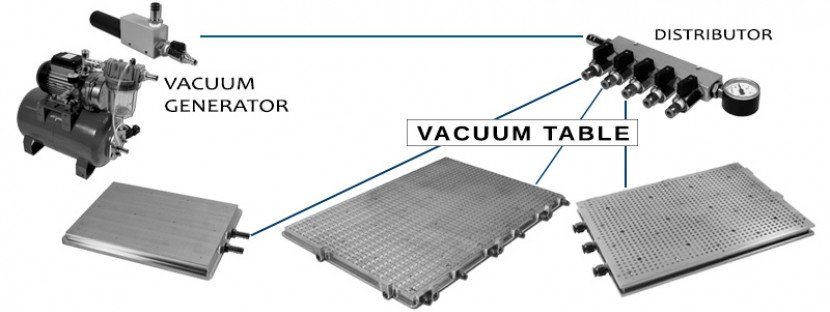

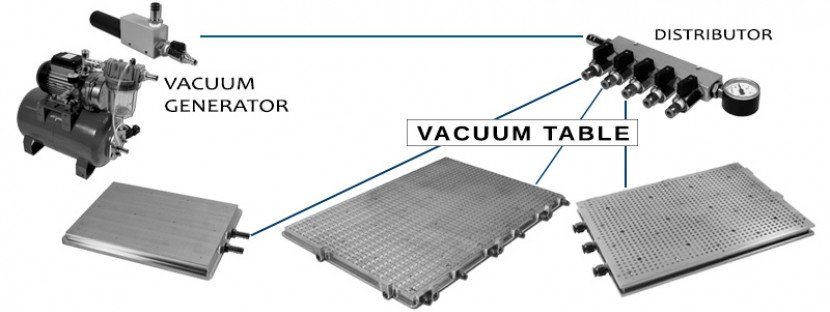

La série RAL Pro

- Fixez la table à vide à votre rainure en T à l'aide de pinces sur votre machine hôte et attachez-la à la lèvre autour de la table.

- La série RAL Pro étant équipée d'un Venturi et d'un collecteur intégrés, il suffit de connecter le Venturi à votre générateur de vide. générateur de vide.

- Retirez une ou plusieurs (en fonction de la taille de votre pièce) des vis sans tête de la surface de la table.

- Utilisez le cordon en caoutchouc pour créer un joint autour de votre pièce.

- Placez votre pièce sur le dessus.

La série ST & SEAL

- Fixez la table à vide à votre rainure en T.

- Insérez le tuyau fourni dans les trous de la table d'aspiration situés sur un côté.

- Si vous utilisez un aspirateur, fixez l'adaptateur à celui-ci et les raccords de votre tuyau à partir de votre table d'aspiration.

- Placez le tapis en caoutchouc fourni sur la surface de la table en veillant à couvrir autant de trous que possible.

- Placez votre pièce sur la table et mettez votre aspirateur en marche.