Which vacuum table is right for you?

With a substantial choice of vacuum tables it can be difficult to determine which would be best suited for your needs.

However there are some basic principals that can be applied that should lead you to a conclusion on which type is best suited to your needs.

Vacuum tables are typically split into two main categories; grid (also referred to as grid raster) and hole grid (also referred to as hole matrix).

Grid / Raster Tables

Grid vacuum tables are usually a more economical choice as their requirement on vacuum generator is low. An inexpensive compressed air generator such as a Venturi is sufficient along with a compressor or even a domestic vacuum cleaner.

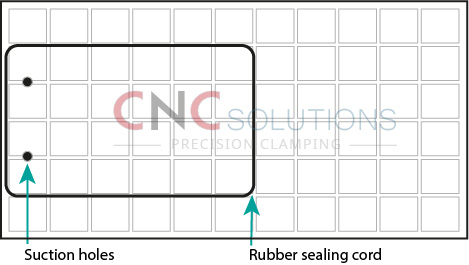

To maintain a good level of clamping force around your part rubber sealing cord is positioned close to openings and recesses within the table grid. With the workpiece placed directly onto the table surface a high accuracy of milling can be achieved. If you're intending on milling smaller work pieces you can add an adapter mat to secure in place whilst machining.

Break-through milling (cutting all the way through) of small workpieces is possible by placing a PVC mat on the table surface and underneath the workpiece. Then cutting holes around your workpiece parts smaller than the workpiece. For example, a round part with a diameter of 100 mm needs a diameter cut of 90 mm into the PVC mat.

Once setup your workpieces can be milled without any need for additional working afterwards and is a good option for batch production of a series of small parts. However, due to the cutting and reuse of the PVC mat the setup procedure can be lengthy especially if your workpieces differ.

Our range of grid vacuum tables:

| R Series | Suitable for wood working and light metal work only. |

| RAL Series | Narrower grid than the R Series, includes workpiece stops and a thread grid on the surface. |

| RAL Pro Series | Development of the RAL Series with integrated Venturi vacuum generator and a steel thread grid. |

| All in One Kits | R Series and RAL Series vacuum clamping kits. Exceptionally good value all in one clamping systems with everything you need to get started. |

Hole Grid / Matrix Tables

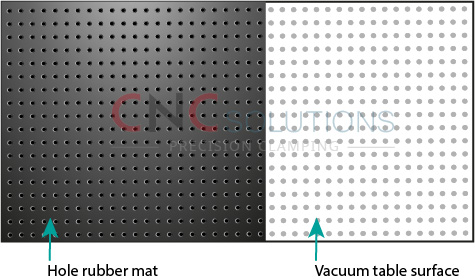

Hole grid tables consist of a series of holes drilled into the table surface. With a hole rubber mat, placed on the table surface, you can position and re-position your workpiece quickly and easily whilst break-through milling all in one procedure. The mat acting as a sacrificial material and protecting the table surface when through-milling at around a depth of 0.2 mm.

However, to compensate, a vacuum pump with a high differential pressure is required. Vacuum pumps that work well with hole grid tables are dry running vane pumps due to their high flow rate and low maintenance.

Or if clamping a large semi-porous work piece where there is potential for substantial air leakage a side channel blower is recommended.

If you are working with metals you may be using coolant. If so you'll need a pump such as a liquid ring. These pumps re-circulate the liquid to maintain constant cooling and separate out surplus swarf.

Our range of hole grid vacuum tables:

| ST Series | An inexpensive beginner model, good for milling wood or plastics but not recommended for metal working. |

| SEAL Series | Development of our ST Series with the addition of an aluminium base plate. With the extra rigidity this table series is suitable for light metal working. |

| GAL Series | Made from 100% cast aluminium and with switchable vacuum sections. The GAL Series has a huge amount of vibration absorption. Suitable for heavy milling especially metal working. |

| GR Series | Our flagship vacuum table the GR Series combines all the features of our GAL Series with the addition of a grid of steel thread bushings and workpiece stops. |