Starter vacuum clamping kit 2012

0

16248

Elevate your machining projects with our custom T-slot plates, manufactured to meet the highest standards of precision. At CNC Solutions, we offer tailor-made solutions, allowing you to choose from two exceptional materials: tempered cast aluminium o..

0

15856

In the world of manufacturing and precision engineering, one size does not fit all. That's where our custom-made vacuum tables come into play, providing tailor-made solutions to meet your unique design and specification needs. We take pride in our co..

0

39866

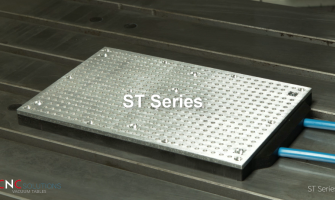

Introducing our new slim line vacuum table series with a focus on low cost, high air flow with a minimal vacuum pump requirement. Our most versatile and cost effective vacuum table yet!It's low height of 11 mm and lateral 3D printed port connector se..

0

20331

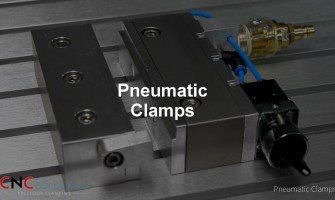

Whatever you are machining, creating a firm hold on your part is essential to milling with flexibility and precision. Vacuum and mechanical clamping are two of the most common methods used each with their own advantages and disadvantages.Vacuum Clamp..

0

36960

With a substantial choice of vacuum tables it can be difficult to determine which would be best suited for your

needs.

However there are some basic principals that can be applied that should lead you to a conclusion on which type is best suited t..

0

19179

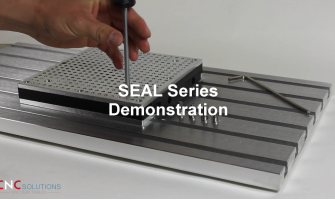

Although it may vary depending on your setup these instructions can provide a rough guide to get you up and running

in no time.

Should you have a specific question not answered here, contact

us or talk to us on live chat.The R Series..

0

27764

Getting the right vacuum pump is essential in ensuring your workpieces are firmly vacuum clamped in place.

The size of vacuum pump required is not proportional to the size of vacuum table.

With the knowledge of your workpiece material and the type of..